Razvoj i proizvodnja električnih vozila u Hrvatskoj

Development and Production of Electric Vehicles in Croatia

Prof. dr. Zvonko Benčić

FER, Sveučilište u Zagrebu (University of Zagreb), 2014.

Gledajući slike i čitajući već letimično tekstove sigurno ćete se zapitati tko su bili ti ljudi koji su razvijali i proizvodili gradska, prigradska i željeznička tračna vozila te podmornice na električni pogon. Samo nekolicina od tih ljudi zabilježena je u tvorničkim novinama i časopisima. Još ih je manje zabilježeno u spomenicama i monografijama različitih tvrtki i poduzeća. Svatko od onih koji su razvijali i proizvodili vozila i plovila mogao bi ispričati svoju povijesnu priču. Zadatak je povjesničara (i kroničara) da prepozna činjenice o kojima se većina slaže i da napiše povijest istinitu za većinu. No i priče povjesničara će se razlikovati u izboru i interpretaciji činjenica. Razvoj i proizvodnja vozila u Hrvatskoj započela je 1951. godine izradom prototipa tramvaja. Zatim slijedi miljokazi: trolejbus, diodna lokomotiva, tiristorska lokomotiva, tiristorizacija diodnih lokomotiva, čoperski tramvaj, tranzistorski tramvaj pa sve do tranzistorskog elektromotornog vlaka 2011. godine. Razvoj i proizvodnja elektroopreme za podmornice započela je 1970. godine razvojem i izradom glavnog i pomoćnog pogona velike podmornice. Zatim je uslijedio razvoj i izrada pomoćnog i glavnog pogona male podmornice. Razvoj diverzantske ronilice kao i razvoj podmornica je prekinut raspadom Jugoslavije 1990. godine. U Hrvatskoj razvoj i proizvodnja vozila je neprekinuta više od 60 godina. Tvorničko znanje (većim dijelom nenapisano znanje, tzv. prešutno znanje) neprekinuto se prenosilo kroz generacije. Diodna lokomotiva omogućila je razvoj tiristorske lokomotive, tiristorska lokomotiva modernizaciju i tiristorizaciju diodnih lokomotiva, tranzistorski tramvaj razvoj tranzistorskog elektromotornog vlaka. Lako je inovirati, ako se ima što inovirati! Glede inovacija, razvoja i održivosti naroda apsurdna je preporuka Bolonjske deklaracije da „ ... sadržaj fakultetskog studija treba biti relevantan za radno mjesto“. Na fakultetu treba steći znanja (većim dijelom zapisana znanja) koja omogućuju otvaranje radnih mjesta. Tehničar ne može bez političara. Političar mora osigurati kontinuitet proizvodnje, on mora biti svjestan da otpuštanje radnika u svezi s ukidanjem proizvodnje znači gubitak znanja. Prof. Zlatko Plenković, prvi direktor Elektrotehničkog instituta Rade Končar, u Glasniku Akademije tehničkih znanosti Hrvatske iz 2000. godine (vol. 7, br. 3) je napisao: „ ...ali mislim da bi hrvatska diplomatska predstavništva trebala uspostavljati kontakte s potencijalnim investitorima i pomoći našim proizvođačima da dođu do posla, kako to i rade strana diplomatska predstavništva u Zagrebu”. Prof.dr. Zvonko Benčić |

While looking at the images and reading superficially through the texts, you will surely wonder about the people who had developed and produced the urban, suburban and railway rolling stock, as well as electrically-driven submarines. Only a few of them were noted down in the factory newspapers and magazines. Even less were recorded in memorials and monographs of various companies and enterprises. Each and every one of those who developed and produced vehicles and vessels could tell his own historical tale. The task of historians (and chroniclers) is to recognize the facts generally agreed to be real and write history considered authentic according to the opinion of the majority. However, even the stories told by historians will differ in the choice and interpretation of facts. The development and production of vehicles in Croatia started in 1951 by a tram prototype. This was followed by several key mile-stones: trolley bus, diode type locomotive, thyristor type locomotive, thyristorisation of diode type locomotives, chopper trams, transistor tram, all the way to the transistor electric multiple unit (EMU) in 2009. The development and production of electrical equipment for submarines started in 1970 by developing and producing the main and auxiliary propulsion for a large submarine. This was followed by the development and production of the auxiliary and main propulsion for a small submarine. The development of a diversion underwater vehicle, as well as the development of submarines was suspended because of the breakup of Yugoslavia in 1990. In Croatia, the development and production of vehicles has lasted without interruption for more than 60 years. Factory knowledge (mostly unwritten, so called tacit knowledge) has been passed on continuously through generations. Diode type locomotive enabled the development of thyristor type locomotive, the thyristor type locomotive enabled the modernization and thyristorisation of diode type locomotives, the transistor tram gave rise to transistor EMUs. It is easy to make innovations when there is something to innovate! When it comes to innovations, development and national sustainability, the recommendation in the Bologna declaration that “...the contents of higher education studies should be relevant for one’s working position” is absurd. Higher education should provide knowledge (mostly written knowledge) which would enable the opening of new work places. A technician cannot do without a politician. A politician has to ensure the continuity of production; he has to be aware that laying off workers due to the cut down in production means losing knowledge. Prof. Zlatko Plenković, the first manager of Electrical Engineering Institute Rade Končar wrote in the Herald of the Croatian Academy of Technical Sciences in 2000 (vol. 7, no. 3): “…but I believe that Croatian diplomatic representations should establish contacts with potential investors and help our producers to obtain jobs, as foreign diplomatic representatives in Zagreb do”. Prof.dr. Zvonko Benčić |

Priredili / prepared by

dr. sc. Ivan Bahun (lijevo / left) dr.sc. Zvonko Benčić (desno / right)

1951

| Prototip tramvaja serije TMK 101 (dvoosovinski tramvaj, maksimalna brzina 60 km/h, dužina 11 m, a širina 2,2 m) proizveden je u radionicama Zagrebačkog električnog tramvaja (ZET). Imao je dva istosmjerna motora. Prototip vučnog istosmjernog motora (60 kW, 600 V, 860 okr/min, v. sliku) i cjelokupnu električnu opremu razvila je tvornica Rade Končar (RK). Serijska proizvodnja tramvaja predana je tvornici Đuro Đaković (ĐĐ), dok je serijska proizvodnja motora ostala u RK. Tramvaji serije TMK 101 proizvodili su se u razdoblju 1957.–1965. Prometovali su u Zagrebu (63 kom), Osijeku (8 kom) i Beogradu. Povučeni su iz uporabe 2005.–2008.; zamijenili su ih tramvaji serije TMK 2200. | A prototype of the TMK 101 series (two-axle tram, maximum speed 60 km/h, length 11 m, width 2.2 m) was produced in the workshops of Zagreb Municipal Transit System(Zagrebački električni tramvaj ZET). It had two direct current motors. The prototype of a traction direct current motor (60 kW, 600 V, 860 rev/min, see figure) and the overall electrical equipment was developed by Rade Končar (RK) factory. Serial tram production was given to Đuro Đaković (ĐĐ) factory, while the serial motor production remained in RK. The TMK 101 series trams were produced from 1957 to 1965. They operated in Zagreb (63), Osijek (8) and Belgrade. They were withdrawn from service from 2005 to 2008; they were replaced by the TMK 2200 series trams. |

1955

| Prema licenciji tvrtke Oerlikon te u suradnji s tvornicom Fabrika automobila Priboj (FAP) (Srbija) i tvrtkom Karoserija iz Ljubljane (Slovenija), tvornica Rade Končar (RK) počinje montažu trolejbusa i proizvodnju električne opreme za trolejbuse: vučni motor (103 kW, 600 V, 1410 okr/min), pomoćni dinamo (1200 W, 24 V), motor-kompresorska grupa, pedalni kontroler, otpornik za pokretanje i električno kočenje i oduzimač struje. Tijekom godina isporučeno je za gradove u tadašnjoj Jugoslaviji (Dubrovnik, Ljubljana, Rijeka, Novi Sad, Beograd) više od 100 trolejbusa. | According to the license by the company Oerlikon and in cooperation with Fabrika automobila Priboj (FAP) factory in Serbia and the Karoserija company from Ljubljana (Slovenia), Rade Končar (RK) started mounting trolley buses and producing electrical equipment for trolley buses: a traction motor (103 kW, 600 V, 1410 rev/min), an auxiliary dynamo (1200W, 24 V), motor-compression group, a pedal controller, a resistor for actuating and electric braking and a pantograph. More than 100 trolley buses were delivered during the years for the cities of former Yugoslavia (Dubrovnik, Ljubljana, Rijeka, Novi Sad, Belgrade). |

1960

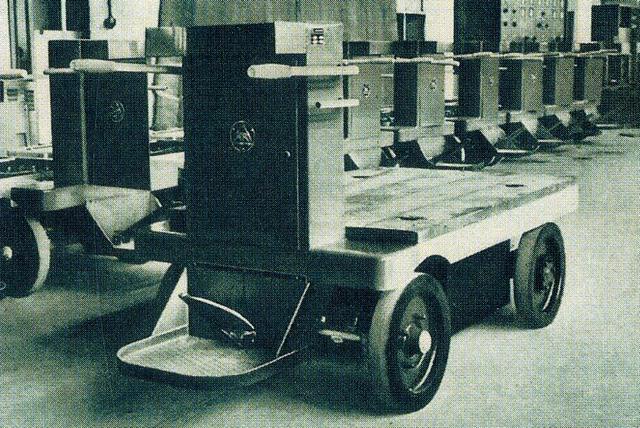

| Pogon tvornice Rade Končar u Sesvetskom Kraljevcu pokraj Zagreba počinje proizvodnju električnih kolica s istosmjernim motorom sa serijskom uzbudom, napajanim iz akumulatorske baterije te s upuštanjem i regulacijom brzine putem otpornika. Tijekom godina ova su električna kolica modernizirana (sjedište za vozača i suvozača). Proizvedeno je više od 500 vučnih kolica. | The facilities of

the Rade

Končar factory in Sesvetski

Kraljevac near Zagreb started with the production of electric trucks with a series-excited direct current motor, fed by an accumulator battery with starting and regulating speed by means of resistors. During the years, the electric truck was modernized (driver and co-driver seat). More than 500 traction trucks were produced. |

1961

| Elektrotehnički institut Rade Končar isporučio dva 6-anodna živina ispravljača za napajanje tramvajske mreže u Osijeku. Ti ispravljači su u cijelosti razvijeni u Končarevom Institutu. Krajem 1962. montirane su ispravljače stanice za gradsku vuču u Zagrebu, Sarajevu, Osijeku i Ljubljani, ukupne instalirane snage veće od 14 MW. | The Rade Končar Electrical Engineering Institute delivered two 6-anode mercury rectifiers for supplying the tram network in Osijek. Those rectifiers were entirely developed in Končar Institute. Rectifying stations, with a total power of more than 14 MW, were mounted for urban traction in Zagreb, Sarajevo, Osijek and Ljubljana by the end of 1962. |

1963

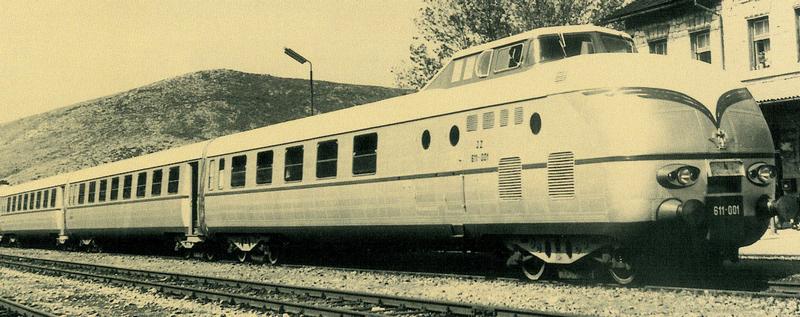

| To je bio prvi diesel-električni vlak s aluminijskom oplatom u Europi (serije JŽ 611). Napredna aluminijska konstrukcija izazvala je pažnju svjetske industrije. Vlak je bio predviđen za prometovanje normalnom širinom kolosjeka (1435 mm) i za maksimalnu brzinu od 120 km/sat. Duljina vlaka preko odbojnika iznosila je 82,12 m, a širina 3 m; imao je 192 sjedišta. Za vuču je imao dva diesel-motora jedinične snage 400 KS. Tvornica Janko Gredelj iz Zagreba (JG) proizvela je tri prototipa, treći prototip isporučen je 1968. Svu električnu opremu (samouzbudne generatore, vučne motore, aparate za niski napon, regulatore uzbude generatora) isporučila je tvornica Rade Končar (udio RK: oko 30 %). Prometovao je na linijama Zagreb – Zadar i Zagreb –Beograd. JG je proizveo još tri garniture aluminijskog vlaka za uskotračnu prugu Zagreb – Samobor (poznatu pod nazivom „srebrna strijela“). Ideja nažalost nije komercijalizirana kako se očekivalo s obzirom na interes koji je pobudio na međunarodnoj razini. | That was the first diesel-electric train with side aluminium plates in Europe (JŽ 611 series). Advanced aluminum construction attracted the attention of the world industry. The train was intended for operation on the normal gauge width (1435 mm) and for the maximum speed of 120 km/h. Train length over bumpers amounted up to 82.12 m, with the width of 3 m: it had 192 seats. It had two diesel-engines with a unit power of 400 HP. The Janko Gredelj factory from Zagreb (JG) produced three prototypes; the third prototype was delivered in 1968. All electrical equipment (self-excited generators, traction motors, low voltage devices, generator excitement regulators) was supplied by Rade Končar (RK share: about 30%). The train operated on the lines Zagreb – Zadar and Zagreb – Belgrade. JG produced three other sets of the aluminum trains for the narrow gauge railway Zagreb – Samobor (also known as “Silver Arrow”). Unfortunately, the idea was not commercialized as expected considering the interest it raised on the international level. |

1965

| Za napajanje željezničke vuče na pruzi Zagreb – Rijeka tvornica Rade Končar isporučila je 60 jednoanodnih živinih ventila. Ispravljač željezničke elektrovučne podstanice projektiran je za napon 3400 V i struju 667 A. Spoj ispravljača bio je 6-fazni sa srednjom točkom; a jedan ispravljač je imao šest jednoanodnih živinih ventila. | Rade Končar delivered 60 single-anode mercury valves for the supply of rail traction on the railway Zagreb – Rijeka. The railway electric traction substation rectifier was designed for the voltage of 3400 V and 667 A of current. The rectifier connection was a six-phase design with a midpoint connection; one rectifier had six single-anode mercury valves. |

1966

| TMK 201 je četveroosovinski tramvaj. Ima četiri motora, svaki snage od 60 kW. Maksimalna brzina je 56 km/h, dužina 14 m, a širina 2,2 m. Kapacitet je 165 putničkih mjesta i imao je mogućnost vuče jedne prikolice. Proizvodio se u tvornici Đuro Đaković. Prometovao je u Zagrebu (18 kom) u razdoblju 1966.–1993. i u Beogradu. Njegova motorna postolja iskorištena za izradu prototipa tramvaja TMK 2100. | TMK 201 was a

four-axle tram. It had

four motors, each with 60 kW of power. Maximum speed was 56 km/h, length 14 m, and width 2.2 m. It had a capacity of 165 passenger seats and the possibility of towing one trailer. It was produced in the Đuro Đaković factory. It operated in Zagreb (18 trams) from 1966 to 1993 and in Belgrade. Its motor base was used for making the prototype of the TMK 2100 tram. |

1970

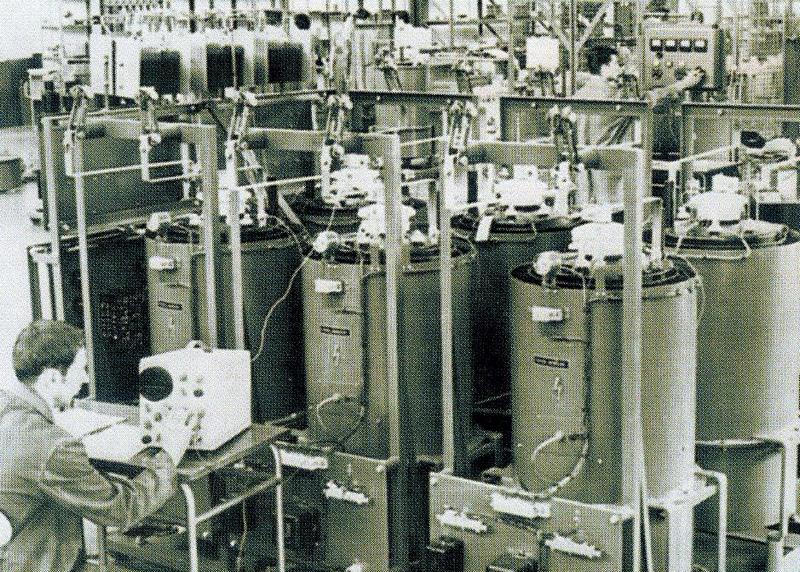

| Prema licencijskoj dokumentaciji tvrtke ASEA, tvornica Rade Končar (RK) proizvela je prvu četiriosovinsku električnu diodnu lokomotivu (Bo'Bo') za 25 kV/50 Hz te isporučila tadašnjim Jugoslavenskim željeznicama (br. 441-030). Kooperanti su bile tvornice Janko Gredelj, Zagreb; Mašinska industrija, Niš; Đuro Đaković, Slavonski Brod; Energoinvest, Sarajevo i Elektrosrbija, Beograd. RK za lokomotivu izrađuje četiri vučna motora snage 850 kW, 10 asinkronih motora za pomoćni pogon, te izvodi kompletnu električnu montažu i ispitivanje lokmomotive (v. sliku montaže diodnih ispravljača). | According to the

license

documentation by the company ASEA, Rade Končar (RK) p roduced the first four-axle electric diode type locomotive (Bo’Bo’) for 25 kV/50 Hz and delivered it to former Yugoslav Railways (no. 441-030). Its subcontractors were Janko Gredelj, Zagreb; Mašinska industrija, Niš; Đuro Đaković, Slavonski Brod; Energoinvest, Sarajevo and Elektrosrbija, Belgrade. RK made four traction motors with 850 kW of power and 10 asynchronous motors for auxiliary drives for the locomotive and performed the entire electrical mounting and testing of the locomotive (see the image showing the mounting of the diode rectifiers). |

1972

| Tvornica Rade Končar proizvela prvu od 75 ugovorene četiriosovinske električne diodne lokomotive (Bo'Bo') za CFR u Rumunjskoj. Lokomotiva se razlikuje od isporučenih za domaće tržište nizom tehničkih pojedinosti: rasvjetnim tijelima i signalnim uređajima, te dodatnoj opremi za udobnost strojovođe. Godine 1974. isporučena je 100-ta lokomotiva za Rumunjske željeznice. Do 1990. proizvedene su 333 diodne lokomotive (25 kV, 50 Hz, 3700 kW, za 120, 140 i 160 km/h); 203 za tadašnje Jugoslavenske željeznice, a 130 za Rumunjske željeznice. | Rade

Končar produced the first

of 75 contracted

four-axle electric diode type locomotives (Bo’Bo’) for CFR in Romania. The locomotive differed from the ones delivered for the local market because of a series of technical details: lighting fixtures and signal devices, as well as additional equipment for the comfort of the driver. In 1974, they delivered the 100th locomotive for the Romanian Railways. By 1990, 333 diode type locomotives (25 kV, 50 Hz, 3400 kW, for 120, 140 and 160 km/h) were produced; 203 for former Yugoslav Railways and 130 for the Romanian Railways. |

1974

| Proizvedena je prva elektrovučna podstanica sa silicijskim diodama. Služila je za napajanje kontaktnog voda napona 3 kV i snage 2×2,2 MW. Instalirana je na pruzi Kopar – Šentilj (Slovenija) u mjestu Čret. Tvornica Rade Končar za tu podstanicu isporučila je kompletnu opremu. | The first electric traction substation with silicone diodes was produced. It was used for the supply of the contact line with 3 kV voltage and 2×2.2 MW power. It was installed on the Kopar – Šentilj railway line (Slovenia) in the village Čret. Končar delivered the entire equipment for this substation. |

1978

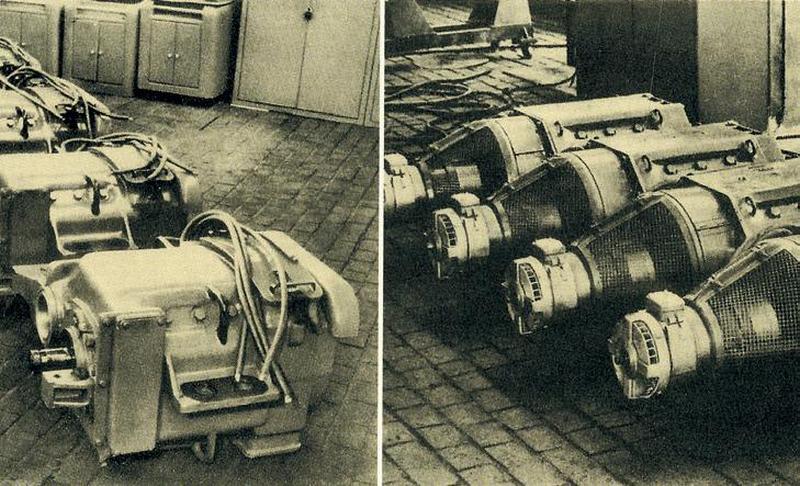

| Klasa Sava bila je klasa jugoslavenskih napadnih podmornica. Izrađivane u razdoblju od 1978. do 1982. Napravljene su dvije jedinice: P-831 Sava i P-832 Drava. Glavne osobine: dužina 55,9 m, površinska brzina 10 čv, podvodna brzina 16,5 čv, dubina zarona 300 m, broj članova posade 35. Glavno naoružanje: šest torpednih cijevi i komplet od deset torpeda promjera 533 mm, a osim toga i mogućnost minoploganja. Početkom Domovinskog rata obje podmornice su odvezene u Crnu Goru gdje su 2004. povučene iz službe. Za dvije podmornice klase Sava Rade Končar je razvio i isporučio glavni elektromotorni pogon (propulzioni istosmjerni motor snage oko 1 MW s tiristorskim regulatorom brzine vrtnje) i pomoćno napajanje (dvije skupine od po tri pretvarača snage 4 kVA/115V/400 Hz u paraleli – v. sliku, punjače pomoćnih akumulatorskih baterija, upuštače istosmjernih motora). Cjelokupnu podmornicu je razvio Brodarski institut u Zagrebu, a proizvelo Brodogradilište specijalnih objekata u Splitu. | Class Sava was a class of Yugoslav attack submarines. They were made in the period between 1978 and 1982. Two units were made: P-831 Sava and P-832 Drava. Main characteristics: length 55.9 m, surface speed 10 knots, underwater speed 16.5 knots, submergence depth 300 m, crew number 35. Main armaments: six torpedo tubes and a set of ten 533-mm diameter torpedoes, along with the possibility of mine laying. At the beginning of the Croatian War of Independence, both submarines were taken to Montenegro where they were withdrawn from service in 2004. Rade Končar developed and delivered the main electromotor propulsion (propulsion direct current motor with about 1 MW power with thyristor speed regulator) and auxiliary power supply (two sets with three power converters 4 kVA/115V/400 Hz in parallel – see figure, auxiliary accumulator battery chargers, direct current motor starters) for two Savaclass submarines. The entire submarine was developed by Brodarski Institute in Zagreb, and it was produced by the Special Vessel Shipyard in Split. |

1981

| Klasa Una bila je klasa diverzantskih podmornica. U razdoblju 1981.–1989. je izrađeno šest podmornica. Projektirane su za tajno polaganje manjih minskih polja ili dostavu diverzanata. Glavne osobine: duljina 18,8 m, površinska brzina 7 čv, podvodna brzina 8 čv, dubina zarona 120 m, broj članova posade 4/6 deverzanta. Raspadom Jugoslavije sve podmornice su odvezene u Crnu Goru, osim P-914 Zete koja se u trenutku sukoba nalazila na remontu. Kasnije je preuređena, produžen joj je trup te je pod oznakom P-01 Velebit do 2001. plovila u sastavu Hrvatske ratne mornarice (HRM) (v. sliku). Početkom 2009. crnogorske vlasti su objavile da se sve podmornice povlače iz službe. Za te podmornice Institut za elektrotehniku Rade Končar je razvio i isporučio glavni propulzioni pogon i sve pomoćne pogone. Cjelokupnu podmornicu je razvio Brodarski institut u Zagrebu, a proizvelo Brodogradilište specijalnih objekata u Splitu. | Class Una was a class of diversion submarines. Six submarines were built in the period from 1981 – 1989. They were designed for the secret laying of small mine fields or bringing diversion military personell. Main characteristics: length 18.8 m, surface speed 7 knots, underwater speed 8 knots, submergence depth 120 m, crew members 4/6. After the breakup of Yugoslavia, all submarines were taken to Montenegro, except P-914 Zeta, which was on the overhaul at the moment of conflict. She was later reconstructed, her hull was elongated and until 2001, she operated under the label P-01 Velebit within the Croatian Navy. At the beginning of 2009, the government of Montenegro proclaimed that all submarines would be withdrawn from service. The Electrical Engineering Institute Rade Končar developed and delivered the main propulsion and all auxiliary drives for those submarines. The entire submarine was developed by Brodarski Institute in Zagreb and she was produced by Special Vessels Shipyard in Split. |

1981

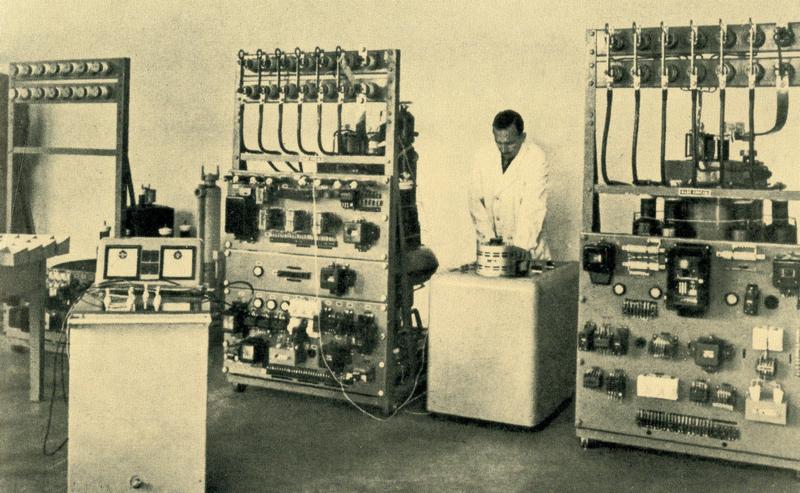

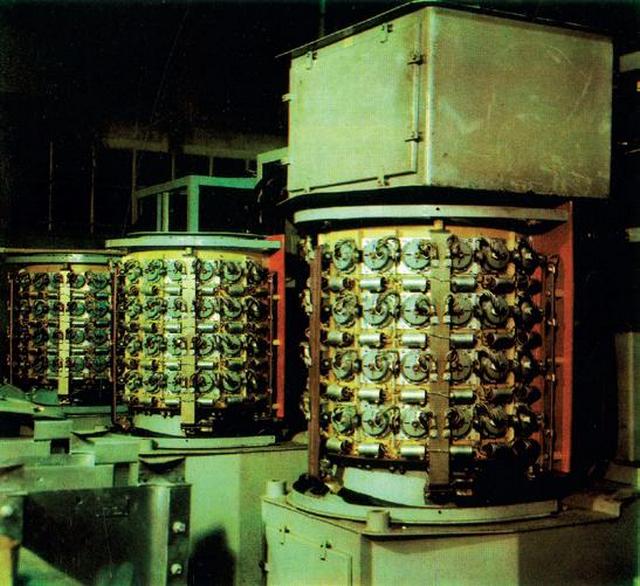

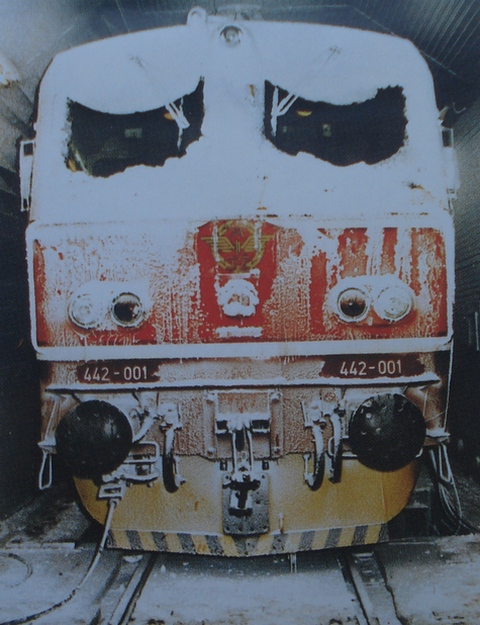

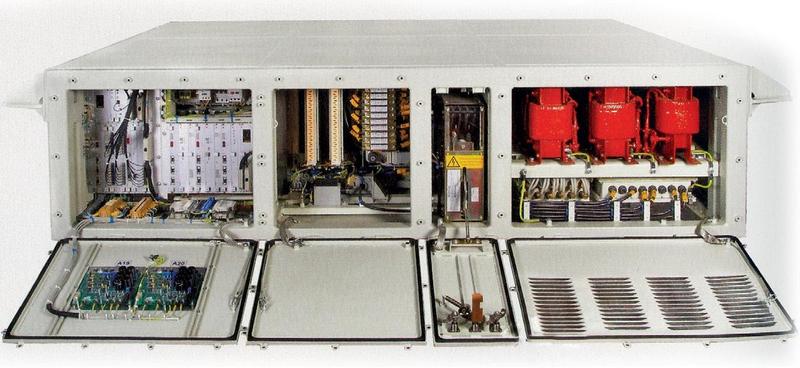

| Predstavljen prototip četiriosovinske tiristorske lokomotive snage 4400 kW, napona 25 kV/50 Hz i brzine do 160 km/sat (br. 442-001). Lokomotiva je u cijelosti razvijena, projektirana, konstruirana i proizvedena u tvornici Rade Končar. Važno je naglasiti da je 85% opreme: vučni motori transformator, tiristorski pretvarači, upravljačka elektronika, sklopni aparati i mehanički dijelovi lokomotive (okretna postolja, sanduk, pneumatska instalacija i uređaji) proizvedeno u Končaru. Vučni motori izrađeni su u novoj tehnologiji, imaju H klasu izolacije i novi način hlađenja. U jednom bloku GEMP 442 (približne izmjere: 2 m × 2 m ×2 m) je sustav od dva tiristorska ispravljača u jednofaznom poluupravljivom mosnom spoju (880 V/1330 A) za napajanje dva vučna motora (gornja slika). U razdoblju 1985.–1990. proizvedeno je ukupno 16 tiristorskih lokomotiva; 15 lokomotiva i danas vozi, a jedna lokomotiva je uništena u Domovinskom ratu. Kasnije je niz tehničkih rješenja razvijenih za tiristorsku lokomotivu (tiristorski pretvarač za napajanje pomoćnog pogona, protuklizna zaštita, regulacija brzine vožnje i dr.) iskorištena za modernizaciju diodnih lokomotiva. | The prototype of a four-axle thyristor type locomotive with 4400 kW of power, voltage of 25 kV/50 Hz and a speed of 160 km/h (no. 442-001) was presented. The locomotive was entirely developed, designed, constructed and produced in the Rade Končar factory. It is important to emphasize that all electrical equipment: traction motor, transformer, thyristor converters, controll electronics and switching devices, was produced in Končar. Traction motors were constructed according to new technology, they have H-class insulation and a new way of cooling. In one block, GEMP 442 (approximate measures: 2m × 2m × 2m) is a system of two thyristor rectifiers in a singlephase half-controlled bridge connection (880 V/1330 A) for the supply of two traction motors (image above). In the period from 1985 – 1990, an overall of 16 thyristor type locomotives were produced; 15 locomotives are still in operation, and one locomotive was destroyed in the Croatian War of Independence. Later, a series of technical solutions developed for the thyristor type locomotive (thyristor converter for the supply of auxiliary drives, antiskid protection, speed regulation, etc.) were used for the modernization of diode type locomotives. |

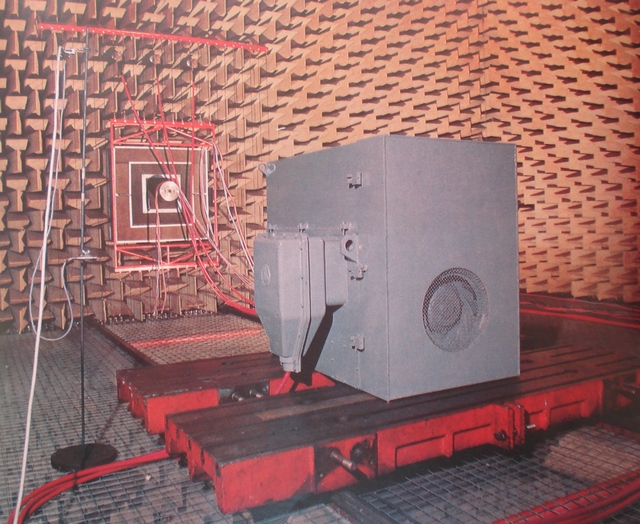

| Akustički laboratorij (gluha

komora) u Končaru,

Zagreb. |

Acoustic laboratory (deaf chamber) in Končar, Zagreb |

| Klimatska ispitivanja

tiristorske lokomotive serije 442, snage 4,4 MW i maksimalne brzine 160

km/h (ispitivanje u ispitnoj stanici ORE, Arsenal u Beču) |

Climatic testin of thyristor locomotive 442 series, 4,4 MW power and 160 km/h maximum speed (Testign in testing station ORE, Arsenal in Vienna) |

| Gluha komora u Končaru,

Zagreb. |

Deaf chamber in Končar, Zagreb. |

| U jednom bloku GEMP 442 (približne izmjere: 2 m × 2 m ×2 m) je sustav od dva tiristorska ispravljača u jednofaznom poluupravljivom mosnom spoju (880 V/1330 A) za napajanje dva vučna motora. | In

one block, GEMP 442 (approximate measures: 2m × 2m × 2m) is a system of

two thyristor rectifiers in a singlephase half-controlled bridge

connection (880 V/1330 A) for the supply of two traction motors |

1986

| Za Željezničko transportno poduzeće Sarajevo (ŽTP Sarajevo) tvonica Rade Končar ugovorila rekonstrukciju 25 elektromotornih vlakova proizvodnje GANZ. Prvi rekonstruirani elektromotorni vlak stavljen je u redoviti promet 1987. pod nazivom „Olimpik ekspres“. | The factory Rade Končar concluded a contract for the reconstruction of 25 GANZ production EMU for the Railway Transport Company Sarajevo (ŽTP Sarajevo). The first reconstructed EMU was put into regular operation in 1987 under the name “Olimpik Ekspres”. |

1986

| Započela proizvodnja nove generacije električnih vozila za unutrašnji transport s tiristorskim čoperima i elektroničkim regulatorom za napajanje i regulaciju brzine vrtnje istosmjernih motora sa serijskom uzbudom (Rade Končar). | The production of a new generation of electric vehicles for internal transport with thyristor choppers and electronic regulators for the supply and speed regulation of serial-excited direct current motors (Rade Končar). |

1987

| Rekonstruiran prvi elektromotorni vlak za ŽTO Sarajevo. | The first EMU was reconstructed for ŽTP Sarajevo. |

1988

| Nakon 12 godina suradnje na tramvajskom programu, za ČKD (Čehoslovačka) isporučen 15000-ti tramvajski vučni motor (Rade Končar). | After 12 years of cooperation on the tram program, the 15000th tram traction motor (Rade Končar) was delivered for ČKD (Czechoslovakia). |

1989

| Modificirana i modernizirana prva od 130 diodnih lokomotiva serije 441 i 461 za ŽTO Beograd. | The first of 130 diode type locomotives from the series 441 and 461 was modified and modernized for ŽTO Belgrade. |

1991

| Suočeni s agresijom na Hrvatsku, končarevci su izradili oklopljeno tračničko vozilo za prebacivanje ljudi i opreme s jedne lokacije na drugu. | Faced with the aggression on Croatia, the people of Končar made an armored train for transferring people and equipment from one location to another. |

1993

| Modificiran i rekonstruiran u Končaru prvi od četiri elektromotorna vlaka (HŽ serija 6111, nadimak Mađar) izgrađenih u mađarskoj tvornici GANZ MAVAG u periodu 1976.–1979. Sustav električnog napajanja mađarskih vlakova je 25 kV/50Hz, maksimalna brzina 120 km/h, masa 145 tona, a duljina 72,4 m. | The first of four EMU (HŽ series 6111, nickname Mađar), built in the Hungarian factory GANZ MAVAG from 1976 – 1979, was modified and reconstructed. The electric supply system of Hungarian trains is 25 kV/50 Hz, maximum speed is 120 km/h, mass is 145 tons, and the length is 72.4 m. |

1994

| U redovitom prometu prvi rekonstruirani i modernizirani tramvaj serije TMK 2100 (br. TMK 2101). Izveden je u tri dijela (dvozglobni), 8-osovinski s pogonskim motorima snage 60 kW koje napajaju čoperi s geitom isklopivim tiristorima (tzv. GTO-tiristori). Vozaču je olakšano upravljanje tramvajem: klimatizirana je vozačka kabina te ergonomski riješen upravljački pult i sjedalo vozača. Cjelokupni projekt rekonstrukcije ostvarila je tvornica Rade Končar. Ukupno je isporučeno Zagrebačkom električnom tramvaju 16 tramvaja te serije. | The first reconstructed and modernized tram from the series TMK 2100 (no. TMK 2101) was put into regular operation. It was made in three sections (two-joint), 8-axle tram with propulsion motors of 60 kW supplied by choppers with gate turn off thyristors (so called GTO-thyristors). Operating the tram is facilitated: air-conditioned driver’s cabin and ergonomic control console and driver’s seat. The overall reconstruction project was realized by Končar. There were 16 trams of this series delivered to Zagrebački električni tramvaj. |

1995

| Završen generalni popravak na prvoj od tri električne lokomotive za Željeznice Federacije BiH. Tek dovršena lokomotiva rastavljena je i specijalnim vozilima otpremljena do Zenice gdje je ponovno sastavljena i puštena u eksploataciju. (Končar) | The overhaul of the first of three electric locomotives for the Railways of the Federation of Bosnia and Herzegovina was completed. The locomotive that had just been finished was disassembled and delivered by special vehicles to Zenica, where it was reassembled and put into operation (Končar). |

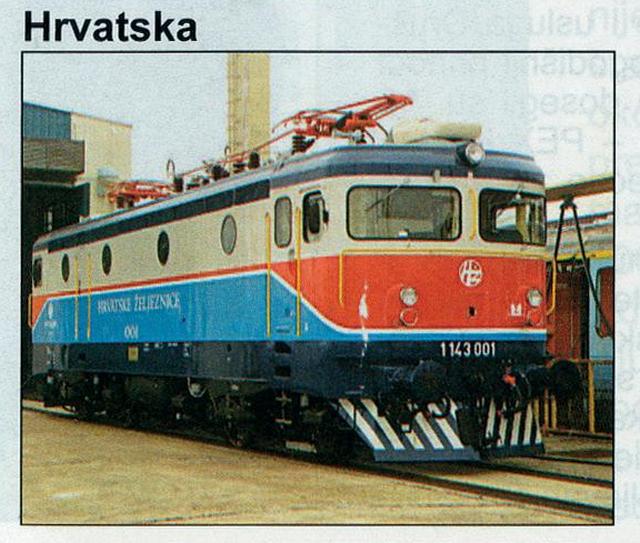

1996

| Završen Končarev projekt modernizacije (ugradnja elektrodinamičke kočnice, opremanje s elektroničkim automatskim sustavom za nadzor brzine i dr.) i pretvorbe četveroosovinskih električnih diodnih lokomotiva (Bo'Bo') u tiristorske (omogućena kontinuirana regulacija brzine vrtnje). Hrvatskim željeznicama isporučena prva od 26 tiristoriziranih lokomotiva (serije HŽ 1141). Zatim su uslijedile isporuke moderniziranih i tiristoriziranih lokomotiva: za Željeznice Federacije BiH, za Turske željeznice, za Bugarske državne željeznice, za Makedonske željeznice, za Željezničko transportno poduzeće u Beogradu, za Rumunjske željeznice. | Končar completed its project of modernization (installment of electrodynamic brakes, equipping with electronic automatic system for speed control, etc.) and transforming of four-axle electric diode type locomotives (Bo’Bo’) into thyristor type locomotives (enabling a continuous speed regulation). A total of 26 thyristorised locomotives was delivered to Croatian Railways (HŽ 1141 series). This was followed by deliveries of modernized and thyristorised locomotives: for the Railways of the Federation of Bosnia and Herzegovina, for Turkish State Railways, for Bulgarian State Railways, for Macedonian Railways, for the Railway Transport Company in Belgrade, for Romanian Railways. |

1997

| U končarevom Institutu za elektrotehniku razvijen prototip četverosistemskog statičkog pretvarača (VIS-50) za napajanje trošila u klimatiziranim putničkim vagonima. Pretvarač je izveden u novoj tehnologiji s IGBT tranzistorima i upravljan je mikroprocesorom. Do kraja 2004. isporučeno je HŽ-u 38 pretvarača. | Končar Electrical Engineering Institute developed a prototype of a four-system static converter (VIS-50) for the supply of energy consumers in air-conditioned passenger cars. The converter was made by means of a new technology with IGBT transistors and was managed by a microprocessor. Until the end of 2004, 38 converters were delivered to Croatian Railways. |

1999

| Završen Končarev projekt modernizacije i pretvorbe šesteroosovinskih električnih diodnih lokomotiva (Bo'Bo') u tiristorske. | The Končar project of modernization and transformation of six-axle electric diode type locomotives (Bo’Bo’) into thyristor type locomotives for Bulgarian State Railwayswas completed. |

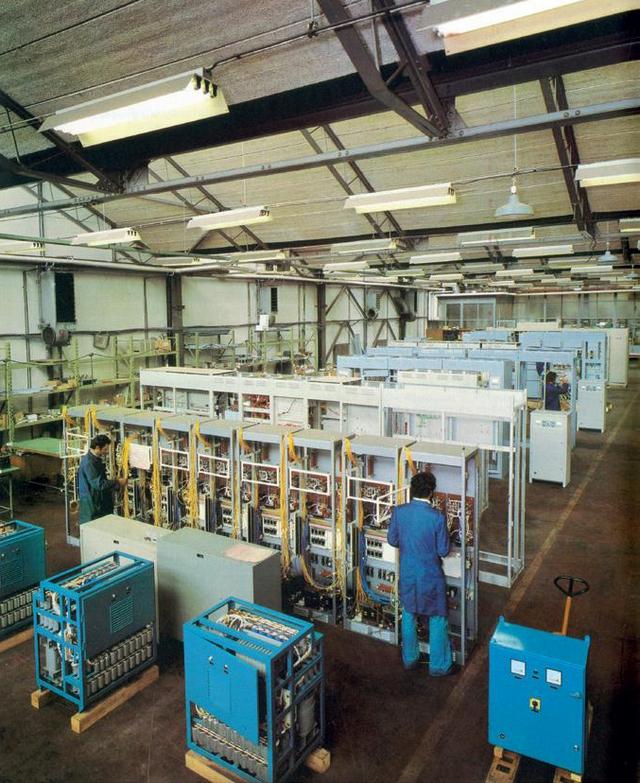

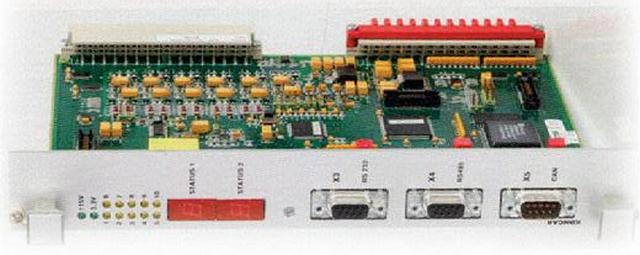

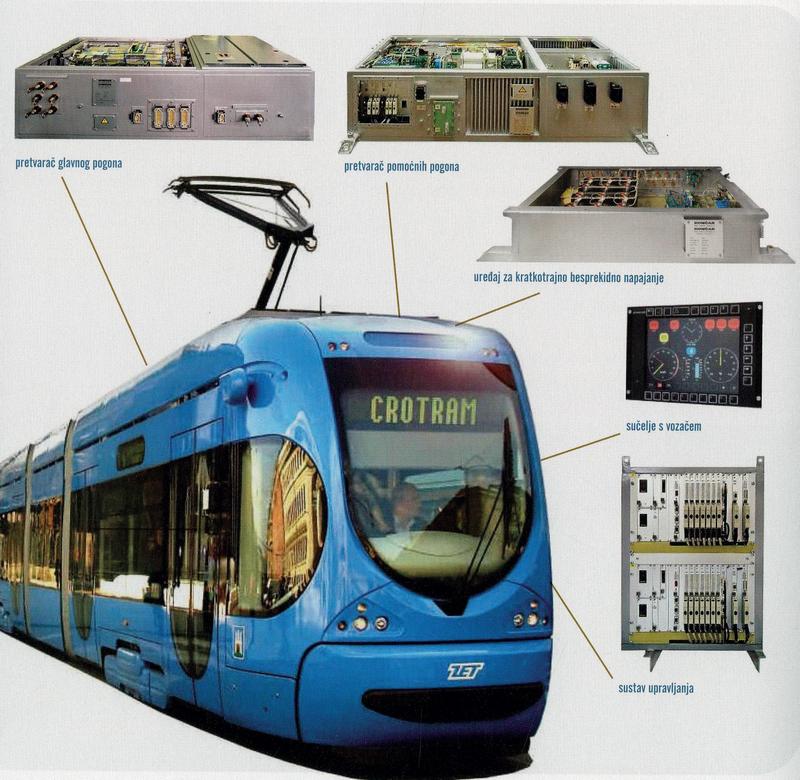

2005

| Konzorcij CROTRAM (Đuro Đaković, Končar, TŽV Gredelj) predstavio niskopodni tramvaj serije TMK 2200 (br. TMK 2001). Izrađen je za nazivni istosmjerni napon od 600 V i za kolosjek širine 1 m. Duljina tramvaja je 32 m, širina 2,3 m i visina 3,4 m. Pod tramvaja na ulazu je na visini 30 cm od ceste. Najveća brzina je 70 km/h. Končar je razvio računalne sustave (v. sliku), elektroničke i energetske pretvarače, vučne motore, postolja te obavio završnu montažu. TŽV Gredelj je razvio i izradio sanduk. Do 2010. isporučeno je 140 kompozicija tramvaja za grad Zagreb. | The consortium CROTRAM (Đuro Đaković, Končar, TŽV Gredelj) presented the TMK 2200 series (TMK nr. 2001) low-floor tram. It was made for nominal direct current voltage of 600 V and a 1-m wide gauge. The tram length was 32 m, width 2.3 m and height 3.4 m. The tram floor at the entrance was 30 cm above road level. The highest speed was 70 km/h. Končar developed computer systems (see image), electronic and power converters, traction motors, bases and it performed all final vehicle mountings. TŽV Gredelj developed and produced body sections. By May 2010, a total of 140 tram compositions were delivered for the city of Zagreb. |

2007

| Eksploatacijska ispitivanje niskopodnog tramvaja TMK 2263 u Finskoj, u uvjetima rada ovog klimatskog područja. | Exploitation testing of the TMK 2263 low-floor tram in Finland in local climate conditions. |

2008

| Do 2008. godine, modernizirane i tiristorizirane su 124 lokomotive, a još 8 lokomotiva do 2012. godine. | A total of 124 locomotives were thyristorised by 2008 and another 8 locomotives by 2012. |

2009

| Prototip niskopodnog vlaka

isporučen za

Željeznicu Federacije Bosne i Hecegovine (ŽFBH) za potrebe regionalnog

putničkog prometa. Duljina mu je bila 75 m, s najvećom brzinom od 160

km/h, a mogao je povesti 500 putnika. Putnički prostor je jedinstvena cjelina duž cijelog vlaka, bez pregrada i stepenica, a visina poda optimalna je za perone visine 550 mm. Vlak ima 8 vrata za brzu izmjenu putnika te klimatiziran putnički prostor i vozačke kabine. Sanduk je četverodijelna zavarena čelična konstrukcija povezana zglobovima. Na konstrukciju se lijepe oplate, izvedene iz aluminijskih sendviča, te prozori. Sva postolja imaju sustav zračnog ovjesa, dva krajnja okretna postolja su pogonska, a tri slobodna postolja su tipa Jacobs. |

A prototype of the

low-floor EMU was

delivered to the Railways of the Federation of Bosnia and Herzegovina

(ŽFBH) for the needs of regional railway passenger transport. It was 75

m long, with the maximum speed of 160 km/h and it took up to 500

passengers. The passenger area is a unique space throughout the train, without compartments and stairs, and the height of the floor is optimal for 550 mm high platforms. The train has 8 doors for a fast exchange of passengers, as well as an air-conditioned passenger area and driver’s cabin. The body is a four-section welded steel construction connected with joints. Side plates, made of aluminum sandwiches and windows are glued to the construction. The two end bogies are powered, and the three middle ones are trailer bogies of Jacobs type. |

2009

| Isporučen prvi niskopodni tramvaj podserije TMK 2200-K za Zagrebački električni tramvaj. Ima tri modula, pa je u odnosu na tramvaje serije TMK 2200 kraći za 11,26 m. Može primiti 120 putnika. Sve ostale karakteristike tramvaja su identične karakteristikama tramvaja serije TMK 2200. | The first low-floor tram from the subseries TMK 2200-K was delivered for the Zagrebački električni tramvaj. It has three modules, so in relation to the TMK 2200 series trams, it is shorter by 11.26 m. It can take up to 120 passengers. All other characteristics of the tram are identical to the characteristics of the TMK 2200 series tram. |

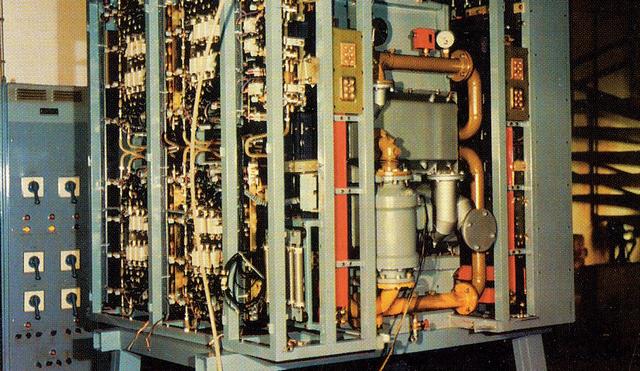

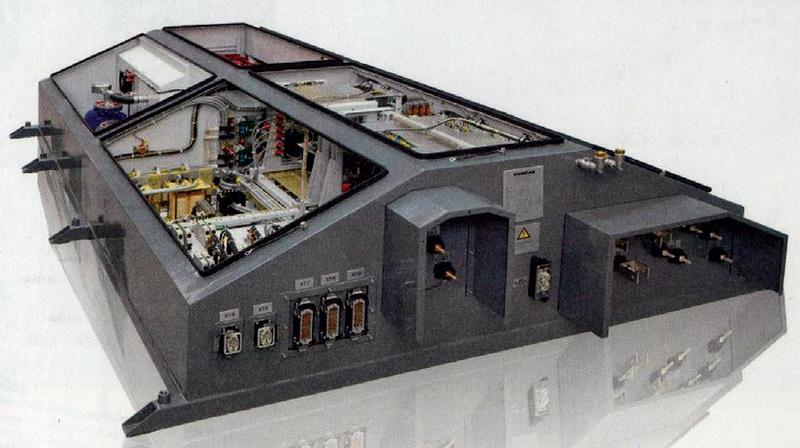

2009

| Trofazni asinkroni vučni motori, napajani iz elektroničkih IGBT pretvarača (v. sliku pretvarača glavnog i pomoćnog pogona) omogućuju visoka ubrzanja u pokretanju (> 1 m/s2) i vožnju maksimalnom brzinom od 160 km/h. Vučna sila pri pokretanju 200 kN, a trajna snaga na kotačima je 2000 kW. Sustav upravljanja i dijagnostike VCU je mikroprocesorski sustav, povezan s podsustavima vlaka modernim komunikacijskim protokolima koji omogućuje spajanje do tri vlaka u jednu kompoziciju. | Three-phase asynchronous traction motors, supplied by electronic IGBT converters (see the image of main and auxiliary drive converter), enable fast acceleration in movement (>1 m/s2) and driving at the maximum speeds of 160 km/h. The starting traction force is 200 kN and continuous power at the wheels is 2000 kW. The control and diagnostics system (VCU) is a microprocessor system, connected with train subsystems through modern communication protocols, which enables the connection of three trains in a single entity via automatic couplings. |

| Ovo rješenje predviđeno je, uz manje prilagodbe, i za gradsko-prigradski promet. U vlak je ugrađena najsuvremenija oprema, razvijena, projektirana i proizvedena u Končaru (sustavi upravljanja i komunikacije, pretvarači, postolja, sanduk) te pojedini dijelovi domaćih kooperanata, tako da udio domaće proizvodnje prekoračuje 70 %. Promotivna vožnja bila je 2012. na relaciji Sarajevo – Mostar – Sarajevo. | This solution, with minor adjustments, was intended also for urban and uburban transport. The most modern equipment, developed, designed and produced in Končar (control system, converters, transformers, traction motors, bogies, etc) and certain parts made by local subcontractors were built into the train, therefore the share of local production exceeded 70%. EMU is in regular traffic from June 2012th on the relation Sarajevo – Mostar – Sarajevo. |

2011

| Isporučen Hrvatskim željeznica

prvi niskopodni elektromotorni vlak (HŽ serija 6112) za regionalni

promet proizveden u konzorciju tvrtki Končar i TŽV Gredelj. Prije

narudžbe Hrvatskih željeznica, već je proizveden vlak istog tipa za

Željeznicu Federacije Bosne i Hercegovine. Od 2011. dnevno prometuje na

liniji Zagreb-Vinkovci. Proizveo ga je Končar –

Električna vozila u suradnji

s TŽV Gredelj. |

The first low-floor EMU (HŽ series 6112) was delivered to Croatian Railways for regional transport. The technical solution is based on a train of the same type that had already been produced for the Railways of the Federation of Bosnia and Herzegovina. It has been in regular daily operation on the line Zagreb – Vinkovci since 2011. It was produced by Končar – Electric Vehicles in cooperation with TŽV Gredelj. |

2011

| Isporučen niskopodni 'kratki' elektromotorni vlak za gradsko-prigradski promet. Proiyveden u Končar –Električna vozila, u suradnji s TŽV-Gredelj. | The first low-floor EMUwas delivered to Croatian Railways for urban and suburban transport. It was also produced by Končar – Electric Vehicles in cooperation with TŽV Gredelj. |

2012

| Isporučen Hrvatskim željeznicama prototip dizel-električnog motornog vlaka za regionalni promet. Prometuje na relaciji Zagreb – Kotoriba – Zagreb. Predviđen je za putovanja prosječne duljine 150 km s čestim zaustavljanjima. Ima 209 sjedećih mjesta, a ukupno može primiti 410 putnika. Proizveo ga je TŽV Gredelj u suradnji s poduzećem Končar – Električna vozila. | A prototype of a diesel-electric multiple unit (DMU) was delivered to Croatian Railways for regional transport. It operates on the relation Zagreb – Kotoriba – Zagreb. It was intended for the average trip length of 150 km with frequent stops. It has 209 seating places and it can take a total of 410 passengers. It was produced by TŽV Gredelj in cooperation with Končar – Electric Vehicles. |

LINKS

Končar

Electrical Industry Inc. [PDF]

MORE

PHOTOS

VIDEOS

Đuro Đaković, www.duro-dakovic.com

We express our deep gratitude to Professor Zvonko Benčić and dr. Ivan Bahun of the University of Zagreb, Faculty of Electrical Engineering and Computing, for sending us the text and photos. This presentation is based on "EDPE 2013 – 17th International Conference on Electrical Drives and Power Electronics, Dubrovnik, October 2-4, 2013, Croatia", published by Kiklos d.o.o., Jurjevska 20, 10000 Zagreb, Croatia. Contact information: e-mail: kiklos.hr@hotmail.com .

Prepared

for web by Darko

Žubrinić, 2014

Marijan Ožanić

- Razvoj Končareve tiristorske lokomotive (1) – Uvodna razmatranja

- Razvoj Končareve tiristorske lokomotive (2) – Početak

Prof. dr. Zvonko Benčić: I knjižare zatvaraju, zar ne?

Mr.sc. Marijan Ožanić: Razgovori s poviješću - prilozi za povijest / Velikani hrvatske znanosti

Croatian science

Croatia, An Overview of Its History, Culture and Science